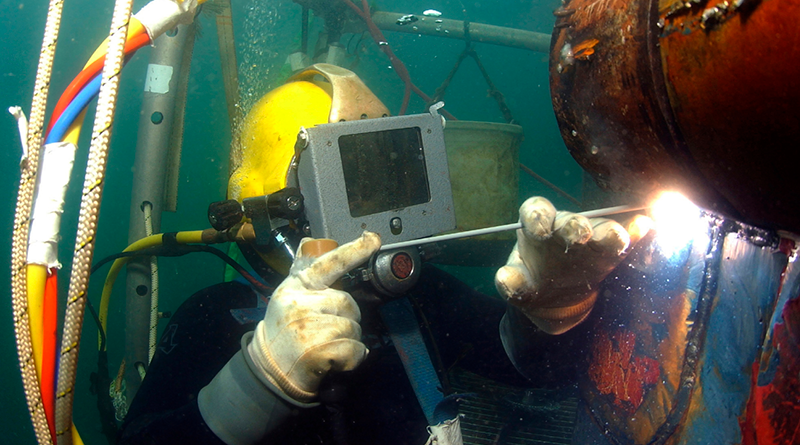

Diving

A leading worldwide supplier of helium and other gases, Linde began supplying helium/oxygen breathing mixtures for offshore oil field diving over 40 years ago. Decades of experience, combined with a global diving gases supply and distribution network, are two key reasons why the commercial diving industry breathes easier with Linde. For pure helium or gas mixtures, in tube modules or in cylinder packs, Linde has the expertise and resources to provide a reliable supply for your dive operations, today and tomorrow.

Supplying the Demand

Diving operations rely on Linde for helium, helium/oxygen, oxygen and nitrogen/oxygen mixtures. We meet customers’ needs through a wide variety of supply systems that provide our quality gases and mixtures.Whatever gas or supply option you choose, your diving gases will be mixed to meet your specifications. Linde operates one of the world’s largest gas blenders at our Louisiana facility. This enhances the speed and accuracy of our gas-mixing operation and also provides supply gas mixtures on very short notice to offshore diving activity in the Gulf of Mexico and nearby locations.

Safety and Quality Commitment

The Linde diving gas group operates under strict safety standards. The accuracy and purity of our gas mixtures and the safety of the diving gases equipment are one of Linde’s priorities. This helps you assure that you receive a diving gas package containing the gas percentages you request every single time.

Diving Cylinders and Containers

8-Tube Module

- Average water volume: 327 cf (9.26 M3)

- Average gas volume when full: 55,061 scf (1,559 M3)

- Average pressure when full: 2,640 psig @ 70° F

- Average tare weight: 23,000 lb (10,443 kg)

- Average weight with He: 23,569 lb (10,691 kg)

- Average weight with O2: 27,560 lb (12,501 kg)

- Length: 240 inches (6.10 meters)

- Width: 96 inches (2.44 meters)

- Height: 51 inches (1.30 meters)

25-Tube Skid

- Average water volume: 128 cf (3.62 M3)

- Average gas volume when full: 23,120 scf (655 M3)

- Average pressure when full: 2,640 psig @ 70° F

- Average tare weight: 13,000 lb (5,897 kg)

- Average weight with He: 13,239 lb (6,005 kg)

- Average weight with O2: 14,915 lb (6,765 kg)

- Length: 158 inches (4.01 meters)

- Width: 60 inches (1.52 meters)

- Height: 64 inches (1.63 meters)

4-Tube Module

- Average water volume: 102 cf (2.89 M3)

- Average gas volume when full: 18,424 scf (522 M3)

- Average pressure when full: 2,640 psig @ 70° F

- Average tare weight: 8,160 lb (3,701 kg)

- Average weight with He: 8,350 lb (3,787 kg)

- Average weight with O2: 9,686 lb (4,393 kg)

- Length: 166 inches (4.22 meters)

- Width: 64 inches (1.63 meters)

- Height: 51 inches (1.30 meters)

25-Cylinder Pack T-Series

- Average water volume: 43.25 cf (1.22 M3)

- Average gas volume when full: 7,812 scf (221 M3)

- Average pressure when full: 2,640 psig @ 70° F

- Average tare weight: 5,500 lb (2,495 kg)

- Average Weight with He: 5,581 lb (2,531 kg)

- Average weight with O2: 6,147 lb (2,788 kg)

- Length: 85 inches (2.16 meters)

- Width: 60 inches (1.52 meters)

- Height: 64 inches (1.63 meters)

16-Cylinder Pack T-Series

- Average water volume: 27.68 cf (0.78 M3)

- Average gas volume when full: 5,000 scf (142 M3)

- Average pressure when full: 2,640 psig @ 70° F

- Average tare weight: 2,800 lb (1,270 kg)

- Average weight with He: 2,852 lb (1,294 kg)

- Average weight with O2: 3,214 lb (1,458 kg)

- Length: 36 inches (0.91 meters)

- Width: 36 inches (0.91 meters)

- Height: 88 inches (2.24 meters)

16-Cylinder Pack LN-Series

- Average water volume: 24.64 cf (0.70 M3)

- Average gas volume when full: 4,082 scf (116 M3)

- Average pressure when full: 2,430 psig @ 70° F

- Average tare weight: 2,550 lb (1,157 kg)

- Average weight with He: 2,592 lb (1,176 kg)

- Average weight with O2: 2,888 lb (1,310 kg)

- Length: 36 inches (0.91 meters)

- Width: 36 inches (0.91 meters)

- Height: 83 inches (2.11 meters)

16-Cylinder Pack K-Series

- Average water volume: 24.64 cf (0.70 M3)

- Average gas volume when full: 3,713 scf (105 M3)

- Average pressure when full: 2,200 psig @ 70° F

- Average tare weight: 2,450 lb (1,111 kg)

- Average weight with He: 2,488 lb (1,129 kg)

- Average weight with O2: 2,757 lb (1,251 kg)

- Length: 36 inches (0.91 meters)

- Width: 36 inches (0.91 meters)

- Height: 83 inches (2.11 meters)

DOT Shipping Name/I.D. Number

Oxygen UN1072

Helium UN1046

Nitrogen UN1066

Cylinder Style/Water Volume

T 1.72 Cubic Feet

K 1.54 Cubic Feet

LN 1.54 Cubic Feet

Compressed Gas, N.O.S. UN1956

(balanced gas/oxygen) Non-oxidizing mixture

(oxygen < 23.5%)

Compressed Gas Oxidizing N.O.S. UN3156

(balanced gas/oxygen) Oxidizing mixture

(oxygen > 23.5%)

Diving Equipment

Cylinder Floor Stand

Designed and built for the safe storage of cylinders up to 12 inches in diameter. Welded construction and epoxy power paint finish provide structural integrity.

| Part Number | Description | Dimensions W x D x H | Weight ld (kg) |

|---|---|---|---|

| PRS-275 | Four Cylinder Floor Stand | 36.5" x 24" x 30" (93 x 61 x 76 cm) | 69 (31) |

| PRS-375 | Six Cylinder Floor Stand | 48.5" x 24" x 30" (123 x 61 x 76 cm) | 81 (37) |

| PRS-475 | Eight Cylinder Floor Stand | 64" x 24" x 30" (163 x 61 x 76 cm) | 93 (42) |

4096 Regulator

Linde's 4096 Regulator is designed to deliver pressure ranges of 0-2500 psi for transfilling of inert gases or Oxygen from a cylinder or bank source and can be panel mounted or ordered with a cylinder connection.

Features and Benefits

- Front and rear panel mountable

- Barstock body: Smooth surface finish

- Pressure range: 0-2500 psig

Specifications

- Maximum inlet pressure 3000 psig

- Gauges: 2-1/2” chrome plated brass

- Temperature range: -40 °F to 140 °F (-40 °C to 60 °C)

- Weight: 5.9 lbs

- Cv: .06

- Ports: 1/4” NPTF

Materials

- Seat: Vespal®

- Seals: Buna-N

- Body: Nickel plated brass barstock

- Bonnet: Nickel plated brass

Ordering Information

| Part Number | Outlet Pressure | Gauges | Description |

|---|---|---|---|

| PRS-4096-1580 | 0-2,500 psig | Inlet 0-3,000 Outlet 0-3,000 | Helium and Argon Service |

| PRS-4096-2540 | 0-2,500 psig | Inlet 0-3,000 Outlet 0-3,000 | Oxygen Service |

Wall Mounted Cylinder Bracket

Government regulations require that compressed gas cylinders be secured when in storage or in use. This cast aluminum bracket, with chain restraint, provides an easy method to secure to a suitable surface.

Protocol Station

Designed to provide a safe, economical way to support regulators, which helps prevent regulator damage.

Pressure Gauges

These 2-1/2” chrome-plated brass gauges allow for monitoring of pressure in system.

Single Row Manifold

Designed for centralized distribution of cylinder gases. Each system comes complete with a stainless steel flexible pigtail.

Rated to 3,000 psi

Ordering Information - Series PRS502BABCD-CGA (Brass) and Series PRS502SABCD-GGA

A Configuration | B Cylinders/Side | C Pigtail Style | D Outlet | CGA Inlet Connections |

|---|---|---|---|---|

| 1: Standard Single Row (right or left extension) | 0: 10 Cylinders | 0: None | 1: 1/4" FPT | Please specify inlet CGA |

| 2: Standard Double Row (two pigtails per station) | 1: 1 Cylinder | 2: Flexible 316 Stainless Steel, 24", with Check Valve | 2: With CGA Adaptor | |

| 3: Standard Duplex (right and left extensions) | 2: 2 Cylinders | 3: Flexible 316 Stainless Steel, 36", with Check Valve | ||

| 4: Compact Single Row (right or left extension) | 3: 3 Cylinders | 6: Flexible 316 Stainless Steel, 72", with Check Valve | ||

| 5: Compact Double Row (two pigtails per station) | 4: 4 Cylinders | |||

| 6: Compact Duplex (right and left extensions) | 5: 5 Cylinders | |||

| 6: 6 Cylinders | ||||

| 7: 7 Cylinders | ||||

| 8: 8 Cylinders | ||||

| 9: 9 Cylinders |

High-Pressure Hoses

Stainless steel 316L flexible hoses are designed for flexible operation.

Ordering Information (Other sizes available upon request)

| Stock Codes | Description | Type | Working | Burst |

|---|---|---|---|---|

| PRSS33S000-36 | 1/4" x 36" SS Pigtail | Double Braid No Guard | 4,100 | 16,400 |

| PRSS33S000-72 | 1/4" x 72" SS Pigtail | Double Braid No Guard | 4,100 | 16,400 |

Diaphragm and Needle Valves

Multi-turn diaphragm valves can be used for primary flow control, while the ¼-turn acts as a quick on/off valve. Needle valves are used primarily for fine flow applications.

Diaphragm Valves

| Part Number | Description |

|---|---|

| PRS533099 | Multi-turn chrome-plated brass 1/4" MNPT z 1/4" FNPT |

| PRS533199 | 1/4-turn chrome-plated brass 1/4" MNPT x 1/4" FNPT |

Needle Valve

| Part Number | Description |

|---|---|

| PRS5500067 | Forged chrome-plated brass 1/4" MNPT x 1/4" MNPT |

Check Valves

Used to ensure that gas flows in only one direction.

Ordering Information

| Part Number | PRSCV5651 |

|---|---|

| Maximum Operating Pressure (psig) | 3,000 |

| Cracking Pressure (psig) | 1.0 |

| Connections Inlet | 1/4" NPT male |

| Body Material | Brass |

| Seal Material | Vitron® |

| Flow Coefficient (Cv) | 0.5 |