ProStar Synchronized Hydraulic Press Brakes - HAP Series

ProStar™ 3-Axis CNC HAP Series

The HAP Series was developed for fabrication jobs where accuracy and production speed is important. Bending angles with maximum precision is made possible using synchronized proportional valve cylinders as in CNC AP machines.

Benefits

- Set-up reduction

- Improved quality

- Improved throughput

- More flexibility

- Improved abilities

Promecam quick-release clamps and reliable Heorbiger-Rexroth hydraulics come standard in the HAP Series. Optional equipment is available to customize your machine to your type of work.

Available SmartClamp Quick-change Tool System

Innovative one-touch tool changes are a powerful productivity boost for the HAP Series.

Standard Features:

- Modern CNC controls

- Promecam quick-release clamps

- Welded high tensile strength steel

- Automatic back gauge adjustment

- 2 front gauge arm supports

- Automatic calculation for bend angles

- Superior fine resolution linear scales

- Conforming to CE regulations

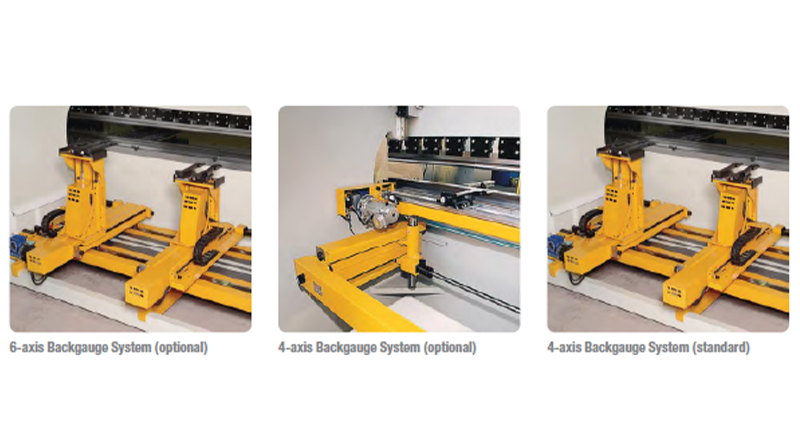

Available Options:

- SmartClamp quick-change tool system

- Sliding front arms with bearing rollers

- Automatic slide greasing system

- Hydraulic punch holders

- Special throat depth (500/600/750 mm)

- Wila anti-deflection system

- Front light guard system

- Laser protection system for die area

- Many offline software options

- Manual crowning devices

Standard and Optional CYBELEC Controllers

The easy-to-operate 60PS controller comes standard in the HAP Series and offers high capacity and fast processing power. Our optional ER70 offers all the features of the 60PS plus 2-D graphical bending simulation, 2-D product drawing, collision control and a wide range of automatic calculations easily readable on a large LCD screen.

DNC 60PS (standard)

- Die and punch programming

- 999 programs/ 13 bending tasks in each

- High accuracy closed circuit beam positioning by speed, pressure and parallel control

- Adjustable speed up, slow down, gain

- Independent axis correction: Y1, Y2, X

- Automatic or programmable back gauge retract feature

- Adjustable short stroke for each part

- Onscreen return-swing-swivel message

- Programmable radius for ideal curves

- Programmable bending angle

- Automatic calculation of bend allowance and unfolded length

- Automatic pressure control

- RS-232 serial port

ER70 Controller (optional)

- 2-D graphical bending simulation

- 2-D graphical product drawing

- 2-D graphical manual collision control

- Delem bending software

- Automatic bend allowance calculations

- Automatic X, R target calculations

- Automatically executed Y1, Y2 position

- Internal radius or bumping calculations

- 10.4" TFT LCD monochrome screen

- Windows® CE operating system

- 64 MB System memory

- Store approx. 1,000 user programs

- Up to 99 sequences per program

- Y1, Y2, X R (max. 4 axes)

- 30/60 punches/dies memory

- 2 USB ports