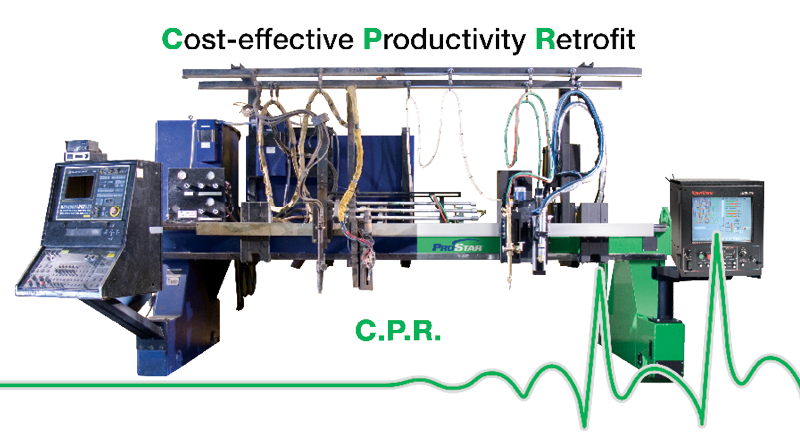

Cutting Machine Retrofits

A Cost-effective, Productivity-focused Retrofit is like CPR for your old cutting machine.

Linde can help breathe new life into your older CNC Cutting Machines with a complete overhaul performed at your facility. We retrofit all controls, drives, gearboxes, motors and plasma or oxy-fuel systems so that your rebuilt machine can perform at today’s high-tech fabrication standards at a fraction of what a new, high-quality machine would cost. But why stop there?

Linde can also add productivity enhancements to your machine such as hole cutting or beveling capabilities, as well as additional cutting stations or lifters. Your rebuilt cutting machine will cut with high-definition precision, reducing scrap and rework, while extending plasma consumables life. In the end, your bottom line will thank you.

Gain many years of service and competitive performance from your existing CNC cutting machine with a top-to-bottom overhaul and equipment upgrade from Linde.

LINDE REBUILDS & RETURNS

Linde can retrofit a new controller and software, CNC drive, motor system, height control and plasma arc system with linear or five-axis beveling, torch system, hole-cutting technology, rails, precision gear rack gantry, drill station and more.

EDGE Connect® value pack

- Hypertherm® EDGE Connect controller with 2 to 4 axes

- Two-station operator’s console, joystick and two speedpots

- >1 GB RAM, Windows® XPE, 15 in. glass touchscreen (SAWT)

- Wireless Networking, LAN, Hypernet

- Autogas support, DXF import, simple shape nesting

- (2) 3515 motors with AL10 planetary gearboxes

- (2) 10/20 ft. double-shielded armature cables

- (2) 10/20 ft. double-shielded encoder cables

- Two-year manufacturer's warrant